This article, regarding the inspection of PRVs in propane service first appeared in the March/April 2015 edition of Propane Canada magazine.

The publishing of the mandatory Annex H of the CSA B51-14 Boilers, Pressure Vessel and Pressure Piping Code, that requires the replacement of Pressure Relief Valves (PRVs) in propane tank service has brought the issue of PRV inspection to the attention of provincial Authorities Having Jurisdiction (AHJ).

The publishing of the mandatory Annex H of the CSA B51-14 Boilers, Pressure Vessel and Pressure Piping Code, that requires the replacement of Pressure Relief Valves (PRVs) in propane tank service has brought the issue of PRV inspection to the attention of provincial Authorities Having Jurisdiction (AHJ).

Mandated Inspection Cycles

The staff at the Fuels Learning Centre were recently contacted by a provincial AHJ to see if we could assist them in researching the history of the use and failures with PRVs in propane tank service and propane tanks. The AHJ is looking at possibly mandating a PRV and propane tank inspection program on a yet-to-be-determined cycle.

We provided a document representing a consolidation of information gained over the years. The document provided points to be considered by the AHJ in making a decision as to the mandating of PRV and tank inspections.

The rationale for putting a mandated documented inspection cycle in place is to ensure that PRVs with a potential for failure are identified and removed from service prior to a failure. We consider a pressure relief valve failure to be when the pressure relief valve fails to activate in an over pressure situation, or opened or partially opened in a non-over-pressure situation. The mechanical components of the valve failed to operate as designed.

Pressure relief valves are required to function under widely varying conditions. Corrosion, aging of the resilient seat disk, and friction all proceed at different rates depending upon the nature of the specific environment and application.

Predicting the safe useful life of pressure relief valves is obviously not an exact science. The conditions to which the valve is subjected will vary widely and will determine its useful life.

We are aware of only one incident, in the past 25 years in which a used external spring type PRV was reinstalled in a propane tank and subsequently failed as per the criteria for a PRV failure.

There are approximately 750, 000 pro-pane tanks in Canada. All of these pro-pane tanks, regardless of size, are equipped with one or more PRV. The majority of the propane tanks are located at residences, farms, and commercial establishments.

An industry standard practice is that the PRVs in propane service are visually looked at for any factors that could impair the operation of the PRV each time the container is filled. This prefill examination is not documented.

Ontario is the only province that currently mandates a documented Inspection of PRVs in propane tank service and the propane tank on a three-year cycle. The person conducting the inspection must hold a valid Record of Training that permits the person to complete the documented visual inspection. The owner of the propane tank must maintain a record of the most current PRV inspection.

If all provinces and territories followed Ontario’s lead and mandated a three-year cycle for PRV and tank inspection it would mean that approximately 750,000/3 = 250,000 PRVs would have to be inspected on an annual basis. The one saving grace in all of this is that the majority of propane tanks are visited at least once annually for refilling and the tank truck operator can be trained to perform the visual PRV and tank inspection while at the site.

If tank truck operators are excluded from being able to perform the documented visual inspection and tank owners are forced to rely on certified propane technicians to conduct the inspection, an impractical situation for compliance will be created. There just are not enough certified propane technicians available to meet the demand for 250,000 annual inspections.

The other issues to be considered include document creation and retention as well as training costs. There will be 250,000 documents to be created and retained per year. While one cannot put a cost on safety, the financial impact of training people to complete the inspection must also be considered for training sufficient staff to meet the demand for inspection.

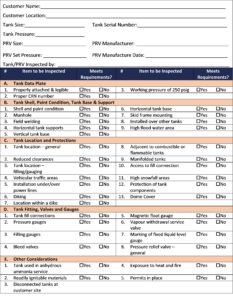

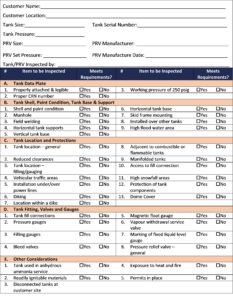

Inspection Checklist

A properly sequenced checklist inspection document, supported by training, can assist the person completing the inspection to obtain all of the information required in a consistent manner. It is also an opportunity to develop a database on the age of PRVs in service to assist in establishing a replacement schedule to meet the requirements of the CSA B51-14 Code.

A properly sequenced checklist inspection document, supported by training, can assist the person completing the inspection to obtain all of the information required in a consistent manner. It is also an opportunity to develop a database on the age of PRVs in service to assist in establishing a replacement schedule to meet the requirements of the CSA B51-14 Code.

We are currently aware of only one AHJ seriously looking at implementing a mandated inspection cycle; however, from a national perspective, it could be a daunting issue that will require a consolidated common national approach by the propane industry to ensure that the industry can meet the regulatory compliance.

History has shown that specific provincial requirements have a tendency at some point to become a national requirement. If this occurs with PRV and tank inspections it will indeed create a potentially burdensome situation.

Available Training

To meet your training needs, the Fuels Learning Centre offers a version of its Tank Truck Operators training course which includes PRV and tank inspection embedded within the curriculum. This means the tank truck operator needs to take only one training program – Loading and Unloading Propane Tank Trucks Including Visual Tank & PRV Inspections (TO04), reducing training time and costs. We also offer a stand-alone inspection course for other personnel who need to learn these skills – Visual Tank & PRV Inspections (SO02).

View PDF

On October 25, 2016, the British Columbia Safety Authority (BCSA) issued Directive D-BP/GA-2016-01 named “Personnel Inspection and Maintenance Certification Requirements for Propane Storage Tanks.”

On October 25, 2016, the British Columbia Safety Authority (BCSA) issued Directive D-BP/GA-2016-01 named “Personnel Inspection and Maintenance Certification Requirements for Propane Storage Tanks.”