This article, related to the importance of organizations to have and maintain effective Standard Operating Procedures, first appeared in the 2016 May/Jun edition of Propane Canada Magazine.

Bill and I were quite surprised, when we received an inquiry at Fuels Learning Centre, from an established propane distributor, going through a government audit, inquiring if we had a “Standard Operating Procedure” (SOP) written for addressing what one must do with an overfilled propane cylinder.

The task of filling propane cylinders is a large part of the propane distribution network to the final user, the consumer, and one would have thought that this safety issue would have been addressed by having a written SOP in place. While the company did not have a written SOP in place, to satisfy the auditor, I am sure that the propane cylinder fillers had been instructed and new how to deal with an overfilled propane cylinder.

While it would appear that the task of dealing with overfilled propane cylinders was being done, there was no written procedure to ensure that all of the regulatory and safety items are addressed, no established written procedure to which an employee can refer to, just word of mouth instructions. As you know, based on the person’s own experience and work habits, verbal instructions are readily changed from person to person which can easily lead to poor dangerous work habits being perpetually put in place.

What is an SOP?

A Standard Operating Procedure (SOP) is a compulsory instruction, a set of step-by-step specific procedure created to help workers carry out routine operations. If deviations from this instruction are allowed, the conditions for these should be documented including who can give permission for this and what exactly the complete procedure will be. The original should be maintained in a secure location while working copies should be authenticated with stamps and/or signatures of authorized persons.

A Standard Operating Procedure (SOP) is a compulsory instruction, a set of step-by-step specific procedure created to help workers carry out routine operations. If deviations from this instruction are allowed, the conditions for these should be documented including who can give permission for this and what exactly the complete procedure will be. The original should be maintained in a secure location while working copies should be authenticated with stamps and/or signatures of authorized persons.

Why do We Need an SOP?

Their purpose is to achieve efficiency, quality output and uniformity of performance while reducing miscommunication and failure to comply with industry regulations, provincial laws or even just your own standards for running your business. Any document that is a “how to” falls into the category of procedures.

Ontario requires a Risk & Safety Management Plan (RSMP) for propane distribution centres and Environment Canada also requires an Emergency Response Plan for certain sized propane tank installations. Other than these two requirements the Regulations, Standards and Codes do not specifically have a requirement for an SOP. In these cases, the development of SOPs is a voluntary guideline that the company can identify as a best practice. Organizations looking to become the best in their industry, demand SOPs as part of defining their standard of work.

Ontario requires a Risk & Safety Management Plan (RSMP) for propane distribution centres and Environment Canada also requires an Emergency Response Plan for certain sized propane tank installations. Other than these two requirements the Regulations, Standards and Codes do not specifically have a requirement for an SOP. In these cases, the development of SOPs is a voluntary guideline that the company can identify as a best practice. Organizations looking to become the best in their industry, demand SOPs as part of defining their standard of work.

SOPs Protect Workers

Workers who are following established SOPs have more confidence that their actions are supported by management, the underlying statutes or regulations, and that they are following industry best practices. Using Standard Operating Procedures regularly leads to fewer corrective actions. If there are legal ramifications to your work, then following your procedures reduces liabilities.

SOPs Protect Customers

Customers are entitled to dependable product or safe service delivery based on established and accepted measures, not on any one worker’s personal values, and not varying from one geographic area to another.

Good & Bad SOPs

The important task of writing policies and procedures rarely gets the respect it deserves. Most people recognize the need for having standard policies, but standard operating procedures often get viewed as a necessary evil.

Just because you have a written SOP does not mean that all is well. Written SOPs can fall into two categories, “good” and “bad”. It’s the bad procedures out there that are the problem – they give all procedures a bad name!

A poorly written SOP can create as much trouble as not having one at all and can, in fact, provide misleading information leading to an incident. It is, therefore, not only good enough to have a written SOP but one that is correct, addresses all of the safety and regulatory issues and falls into the “good” category as listed below.

Good procedures and work instructions provide a way to communicate and apply consistent standards and practices within your organization.

GOOD Standard Operating Procedures:

- save time and mistakes;

- reduce training costs;

- ensure consistent results;

- empower the workforce;

- get read and used; and

- support quality goals.

But, BAD procedures can be as disastrous as no procedures at all!

BAD Standard Operating Procedures:

- cause errors and frustration;

- increase training costs;

- waste time and money;

- detract from quality goals; and

- don’t get read or used.

Writing an SOP

When writing an SOP, make sure to answer the following key questions:

- Who does what? (role or person responsible)

- Which tasks are to be completed? (what to do, how often and to which standard or criteria)?

- What is the outcome when they do it? (deliverables, measures, objective results, desired behaviours)

- Did you answer what needs to hap-pen, clearly?

Work Instructions

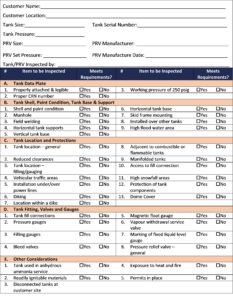

Work Instructions define the “how to” information to complete steps in a task mentioned inside an SOP. Work Instructions are action-focused. They may include a “list” of steps, a checklist, or pictures of dials, switches, or computer screen shots with annotations. Make sure to label the information in a way that tells the user what to expect. Pictures may speak a 1,000 words, but it’s the annotations that clarify the meaning.

Work Instructions focus on “how” typically, the person is to perform the task. While Work Instructions usually assume the individual has the capability in the general area being addressed, SOPs and work instructions are NOT meant to be a substitute for training! Instead, they should be a companion to training and should reflect what is covered in the training.

Updating SOPs

Standard Operating Procedures are living documents that must be reviewed and updated on a regular basis. Regular re-views should address:

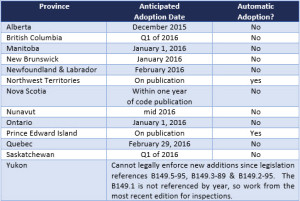

- changes to underlying standards, codes, regulations and interim orders from authorities having jurisdiction;

- changes to equipment used to complete tasks;

- changes to internal corporate policies and guidelines; and

- changes to how supporting training courses deal with specific procedures.

Sample SOP

We have created an example of a typical SOP for handling overfilled propane cylinders by transferring the product into another propane cylinder. Each company is responsible for writing the SOP to meet their specific requirements. How overfilled propane cylinders are handled will depend on the dispensing location and the specific equipment available.