This article, related to Ontario code adoption documents, first appeared in the 2015 Sep/Aug edition of Propane Canada Magazine.

I normally try to write articles on the regulatory and technical issues which apply equally across all provinces and territories. However, with the new 2015 B149 series of codes being published by CSA this past August, many of the Authorities Having Jurisdiction are now in the process of developing code adoption documents to adopt the 2015 versions. I will report on the activities of each Authority Having Jurisdiction as they progress towards the adoption of the 2015 codes.

As previously reported, Ontario issued an Ontario Code Adoption Document (CAD) in August 2014 which continued the adoption of the 2010 editions of CSA-B149.1 and CSA-B149.2. The purpose of this 2014 CAD was to not only continue the adoption of the 2010 Codes in Ontario but to adopt as early as possible many of the 2015 Code requirements that Ontario felt were important to put in place as soon as possible. The 2014 CAD became effective October 1, 2014.

As previously reported, Ontario issued an Ontario Code Adoption Document (CAD) in August 2014 which continued the adoption of the 2010 editions of CSA-B149.1 and CSA-B149.2. The purpose of this 2014 CAD was to not only continue the adoption of the 2010 Codes in Ontario but to adopt as early as possible many of the 2015 Code requirements that Ontario felt were important to put in place as soon as possible. The 2014 CAD became effective October 1, 2014.

The next round of Ontario amendments to the CSA-B149.2 Code will be released January 1, 2016. The 2016 CAD drops the 2015 Code requirements listed in the 2014 CAD.

The 2016 CAD not only adopts the B149.2 but revokes the requirements listed in the 2014 CAD and provides new requirements for the following:

- Adoption of Field Approval Code and Mobile Food Unit Approval Code for appliances on those units that are not approved;

- New requirements for labelling of tanks mounted on OEM and converted vehicles for motive power and for RV for supplying appliances;

- Exemption of vehicular protection for cylinders of 20 lb. or less stored in cabinets;

- New requirements for inspection of tanks and inspection/replacement of relief valves; and

- Annex Q is added for requirements for use of non-refillable cylinders in classrooms in schools.

Primary Amendments

The following are the primary Code amendments/edits that will appear in the 2016 CAD.

Cylinder Exchange

New definition to clarify what a cylinder exchange is, for the purpose of licensing and the respective requirements. Cylinder Exchange means a type of a propane cylinder handling facility where propane in refillable cylinders are sold or other-wise distributed to an end user, with cylinders stored in no more than four (4) cabinets and each cabinet contains no more than 500 lb. of propane.

New definition to clarify what a cylinder exchange is, for the purpose of licensing and the respective requirements. Cylinder Exchange means a type of a propane cylinder handling facility where propane in refillable cylinders are sold or other-wise distributed to an end user, with cylinders stored in no more than four (4) cabinets and each cabinet contains no more than 500 lb. of propane.

Cutting or Welding Applications

When TC-4BWM18 cylinders, with a propane capacity of 40 lb. (18 kg) or less, used in cutting or welding applications are requalified, they are exempt from having a cylinder valve that does not permit the flow of propane until a positive seal has been achieved. When requalifying TC-4BWM18 cylinders, valve replacement may be made by using a valve outlet conforming to the CGA 510 standard, not requiring a positive seal and with a PRV set at 405 psi.

Refueling Equipment Indoors

This CAD requirement is to require all equipment fueled with propane, including ice resurfacing machines, to be subjected to the same requirements. Therefore, clause 5.11.3 in the Code is revoked.

The new clause states that when equipment, such as an industrial tractor, lift truck or ice resurfacing machine, is fueled by propane and is used indoors, the area shall be ventilated in accordance with the requirement of Table 5.1 as found in the code.

Approval Labels for Recreational Vehicles (RVs)

RVs which have permanently mounted propane tanks for fueling the appliances will have to have two labels of approved design, affixed by a licensed conversion centre certificate holder. The labels are to be affixed on the rear window or side window nearest the fill connection, at the door latch, or in the glove compartment.

The CAD requires that the appliances be inspected every 5 years in accordance with the B149.1 and the inspection reports are to be provided to the propane conversion centre. The copy of the inspection report must be no older than 90 days when received by the propane con-version centre.

To inspect an RV will require that a valid G1, G2, RV1 certificate holder inspect the appliances and the inspection of the tank and associated liquid piping and components be inspected by a holder of a valid Internal Combustion Alternate Fuel Technician, Propane (ICE-P) certificate.

Also, the inspection of the tank and associated liquid piping and components is to be carried out at a registered vehicle conversion centre.

Moving propane cylinders from one level to another

The use of passenger escalators is removed as this is not an acceptable practice.

Vehicle Impact Protection

Vehicle impact protection will not be required for protection of 20 lb. propane cylinders where the cylinders are kept in lockable ventilated cabinets of metal construction.

It was submitted by the industry group that it is proven cylinders are well protected with cages of metal construction. The same requirements were adopted in IFC and in the process of adoption in NFPA.

Filling cylinders under 100 lbs. from bulk trucks

The filling of cylinders under 100 lbs. from bulk trucks shall comply with Annex P of the CAD.

The filling of cylinders under 100 lbs. from bulk trucks shall comply with Annex P of the CAD.

Annex P requires that:

- Drawings are submitted and that each location is approved;

- A letter from the local municipality stating that the refueling of propane cylinders does not contravene any applicable zoning bylaws;

- Calculations submitted confirming that Branch Standard No. 9 has been met; and

- Written procedures are available for filling cylinders from a bulk truck.

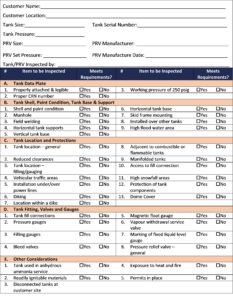

Tank Inspections

All installed tanks will require a recorded tank inspection every 10 years, in accordance with National Board Inspection Code (NBIC) inspection and acceptance criteria.

Pressure Relief Valve (PRV) Inspections

The CAD provides clauses to adopt the requirements in the new edition of B51 and allows a grace period of seven (7) years for tanks greater than 2,500 USWG and ten (10) years for tanks of 2,500 USWG or less. Each operating company should have a plan and start acting as soon as these requirements come into effect.

Pressure relief valves (PRV) of tanks are to be visually inspected periodically to ensure that there are no impediments that will prevent them from operating properly. The frequency of the periodic visual inspection depends on the operating environment and the manufacture’s recommendation.

The PRV inspection is to be recorded at a minimum interval of every five (5) years. The record must include the date of in-spection and the person carrying out the inspection.

The inspection will ensure that:

- the outlet and, where applicable, weep hole is open and free to discharge;

- there are no signs of corrosion, cracks, debris, tampering, or other mechanical damage;

- there is no leakage;

- the discharge is directed to a safe location, and any piping installed is adequately supported and does not obstruct the discharge;

- the seal, where applicable, has not been broken; and

- the rain cap, where applicable, has been installed.

Tanks of greater than 2,500 USWG must have the relief valves rebuilt/certified or replaced every 10 years. All overdue relief valves are to be rebuilt/certified or replaced by January 1, 2023.

Tanks of 2,500 USWG or less must have the relief valves rebuilt/certified or replaced every 25 years. All overdue relief valves are to be rebuilt/certified or re-placed by January 1, 2026.

Tank owners must develop a plan that provides an achievable pathway for full compliance with the PRV replacement requirements for tanks regardless of size within the implementation periods stated above (January 1, 2023 & January 1, 2026). The plan must be developed by July 1, 2016.

Within a ten (10) year period from the implementation of these requirements (seven [7] years for tanks of greater than 2500 USWG), each owner should keep records of the PRV for each in-service tank, including:

- the name of the PRV manufacturer;

- the date on which the PRV was put into service;

- an approval stamp – the PRV must have the UL code symbol on it in accordance with the applicable design code (ANSI/UL 132);

- a record that the set pressure of the PRV meets the specified requirements for the tank;

- a record that the relief capacity in SCFM air conforms to the appropriate rate for the size of the tank; and

- records of this information shall be held by the distributor and may be kept in hard copy or electronic format.

*Not all valves will have a nameplate. If there is no nameplate the markings are stamped into the body of the valve. All valves should be marked with the manufacturer’s name or an abbreviation, the manufacturer’s part number, set pressure, capacity, date or date code for the year of manufacture, and the UL rating code symbol.

Use of Non-Refillable Propane Cylinders in Laboratories/Classrooms in Schools, Colleges, and Universities

The CAD provides an Annex Q to address the use of non-refillable cylinders in classrooms.

The CAD provides an Annex Q to address the use of non-refillable cylinders in classrooms.

In Closing

In this article I have attempted to raise awareness on the issues I believe will most impact the Ontario propane industry. There are a few requirements within the 2016 CAD that are carryovers from the previous 2014 CAD and some requirements with slight amendments to them.

It is, therefore, important that each person who works under the B149 series of codes obtain a copy of the final, approved 2016 CADs for propane storage & handling, natural gas installation, and vehicle conversion codes to become familiar with their requirements. The CADs, when issued, will be available on the TSSA website.

View PDF

On October 25, 2016, the British Columbia Safety Authority (BCSA) issued Directive D-BP/GA-2016-01 named “Personnel Inspection and Maintenance Certification Requirements for Propane Storage Tanks.”

On October 25, 2016, the British Columbia Safety Authority (BCSA) issued Directive D-BP/GA-2016-01 named “Personnel Inspection and Maintenance Certification Requirements for Propane Storage Tanks.”