This article, related to the requirements of bonding bulk delivery vehicles, first appeared in the 2014 Nov/Dec edition of Propane Canada Magazine.

I have recently been involved in a project that looked at the regulatory requirements for bonding between a propane delivery vehicle and the propane container being filled.

The project’s scope included a review of the following documents:

- Transportation of Dangerous Goods Regulations – Part 1 Classification, Clauses 2.13 & 2.14;

- CSA-B622-03 Selection and Use of Highway Tanks, Multi-Unit Tank Car Tanks, and Portable Tanks for the Transportation of Dangerous Goods;

- CSA-B620-09 Highway and TC Portable Tanks for the Transportation of Dangerous Goods;

- CAN/CSA-B149.1-10 Natural Gas & Propane Installation Code Sections 7 & 8;

Canadian Electrical Code;

- National Fire Code of Canada Clause 4.1.8 (4.1.8.2);

- Alberta OHS Code;

- Alberta OHS Explanation Guide;

- BC OHS Regulation;

- NFPA 58 LP Gas Code Handbook Clauses 3.7.1.3 & A3.7.1.3;

- United States OHSA Regulations; and

- Static Electricity in the Propane Industry published by the Propane Education & Research Council (PERC).

Acts, Regulations, Standards & Codes

Transportation of Dangerous Goods Act & Regulations

The handling and transportation of propane is governed by the Transportation of Dangerous Goods (TDG) Act and Regulations. The regulations govern the construction of bulk transport vehicles with respect to the propane tank and attached components used in the transfer to or from the bulk transport vehicle. The TDG Regulations also govern the loading and unloading of the bulk transport vehicle. The TDG Regulations classify propane as a Class 2.1 Flammable Gas.

The handling and transportation of propane is governed by the Transportation of Dangerous Goods (TDG) Act and Regulations. The regulations govern the construction of bulk transport vehicles with respect to the propane tank and attached components used in the transfer to or from the bulk transport vehicle. The TDG Regulations also govern the loading and unloading of the bulk transport vehicle. The TDG Regulations classify propane as a Class 2.1 Flammable Gas.

CSA-B622-09

This Standard is adopted by the TDG Regulations and states under the heading of Loading and Unloading, that “a means of containment shall not be used where a fire hazard exists; precautions have been taken to prevent a difference in electrical potential between conductive surfaces and to ensure safe dissipation of static electricity through bonding or grounding, or both, as appropriate”.

Comment: The Standard stipulates that a container cannot be used where a fire hazard exists and requires that precautions be taken to prevent electrostatic discharge.

CAN/CSA-B149.2 Propane Storage & Handling Code

The Code applies, for purposes of this document, to the storage, handling, and transfer of propane and the installation of containers and equipment to be used for propane at customer locations.

The Code states that all tank trucks, tank trailers, and cargo liners must be designed, fabricated, and marked in accordance with the requirements of CSA B620.

The electrical requirements of the Code and the sections dealing with propane cylinder and tank filling are silent on the subject of controlling static electric charges during the propane transfer between the containers and a propane bulk transport vehicle. However, the Code does state that, where specified for the prevention of fire or explosion during normal operation, ventilation is considered adequate where provided in accordance with the provisions of the Code.

The Code requires that propane is transferred from one container to another by a person who is the holder of a certificate recognized by the authority having jurisdiction. The propane container must be filled in a location that is well ventilated.

Comment: For purposes of this document the CSA-B149.2 Code is silent and does not provide any regulatory requirements with respect to the issues of static electric charge during the process of transferring propane from a propane bulk transport to a consumer’s propane cylinder or tank.

The National Fire Code

The Code does speak to the control of static electric charge, however, the Code states that it does not apply to the transportation of flammable liquids or combustible liquids under the TDG Regulations.

Comment: For purposes of this document the National Fire Code requirements do not apply. The Code references the TDG Regulations when it comes to handling and transporting propane.

Canadian Electric Code

The objective of the Code is to establish safety standards for the installation and maintenance of electrical equipment. The scope of the Code covers all electrical work and electrical equipment operating or intended to operate at all voltages in electrical installations for buildings, structures, and premises. This includes factory built relocatable and non-relocatable structures, and self-propelled marine vessels stationary for periods exceeding five months and connected to shore supply of electricity continuously or from time to time.

Comment: For purposes of this document the Canadian Electrical Code requirements do not apply. The Code does not specifically address the issues of controlling static electric charge during the process of transferring propane from a propane bulk transport vehicle to a consumer’s propane cylinder or tank.

Alberta OHS Code

The Alberta OHS Code states that “if the work requires that the contents of metallic or conductive containers be transferred from one container to another, an employer must ensure that static electricity is controlled while the contents are being transferred.”

Comment: The OHS Explanation Guide when referring to Section 163 (2.1) states that “when transferred into or out of containers, flammable liquids can cause a static charge to build up on the container. This charge could create a difference in voltage potential between the containers, creating the possibility of an incendive spark igniting the vapours from the liquid. Effective control of static electricity can include actions such as grounding and bonding.”

The OHS Explanation Guide published on the Alberta Human Services website clarifies that the product under discussion in Part 10 Section 163 (2.1) is flammable liquids, not a flammable gas such as propane.

For purposes of this document the Alberta OHS Code Part 10 Section 163 (2.1) requirements do not apply. The Code requirements for bonding or grounding are for flammable liquids, not flammable gases such as propane.

B.C. OHS Regulation

The Regulation states that metallic or conductive containers used to transfer flammable liquids must be electrically bonded to each other or electrically grounded while their contents are being transferred from one container to the other.

Comment: While the B.C. OHS Regulations discuss the requirement for Flammable Gases in other clauses within the same section, the specific clause for grounding or bonding references Flammable Liquids only, not Flammable Gases.

For purposes of this document the B.C. OHS Regulations requirements do not apply as they only require bonding or grounding for flammable liquids, not flammable gases such as propane.

NFPA 58 Code

NFPA 58 is an American Code that is not mandated for use in Canada. That being said, NFPA Codes and Standards are often used when an equivalent Canadian Code or Standard does not exist or for comparison of requirements where a Canadian Code or Standard does exist.

On the subject of grounding or bonding, NFPA 58 Code stipulates that grounding or bonding is not required. The NFPA 58 Handbook explains “because liquefied petroleum gas is contained in a closed system of piping and equipment, the system need not be electrically conductive or electrically bonded for protection against static electricity.”

American Occupational Health & Safety Administration (OHSA) Regulations

These regulations state that “since liquefied petroleum gas is contained in a closed system of piping and equipment, the system need not be electrically conductive or electrically bonded for protection against static electricity.”

Observations

Static Electricity

Static electricity is generated when liquids move and come into contact with other materials. If the accumulation of static is sufficient, a spark may occur in the presence of a flammable vapour-air mixture, and ignition may result. Where a static spark and flammable mixture may occur simultaneously, suitable preventative measures are required to avoid ignition.

Propane industry experience has shown that there have been a number of fires and explosions in which an electrostatic charge was the source of ignition. For this to occur liquid propane must be released at a high velocity, creating a mixture of liquid drops, then vapour, air, and water drops (due to condensation of water vapour in the air from the refrigerating effect of vaporizing liquid) can generate an electrostatic charge. This charge might be of sufficient energy to cause ignition of the mixture.

Propane industry experience has shown that there have been a number of fires and explosions in which an electrostatic charge was the source of ignition. For this to occur liquid propane must be released at a high velocity, creating a mixture of liquid drops, then vapour, air, and water drops (due to condensation of water vapour in the air from the refrigerating effect of vaporizing liquid) can generate an electrostatic charge. This charge might be of sufficient energy to cause ignition of the mixture.

High-pressure propane liquid releases as described in the previous paragraph can occur when the pressure relieve valve (PRV) on a liquid-full propane container releases the liquid propane to the atmosphere due to over pressurization of the propane container. PRVs are installed within the 20 percent vapour zone on top of the liquid propane. This type of electrostatic charge is not created during the normal propane transfer process from a bulk transport vehicle to a consumer’s propane cylinder or tank.

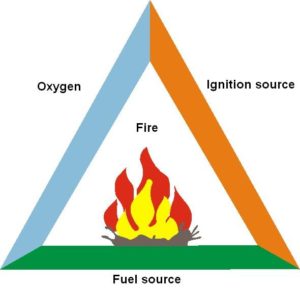

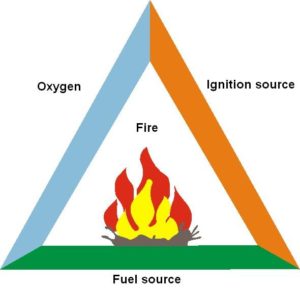

Fire Hazard Analysis

For a fire hazard to exist, three components – fuel, air and an ignition source must be present. The ignition source must occur simultaneously with the fuel vapours and air being mixed at the point of ignition within the fuel’s range of flammability. For propane, the flammability range is 2.4 to 9.5 percent volume in air, and requires an ignition temperature of 493⁰ to 549⁰ C. Below 2.4 per cent, the mixture is too lean to ignite. Above 9.5 percent, the mixture is too rich to ignite. Removing one or more of the three components removes the fire hazard.

For a fire hazard to exist, three components – fuel, air and an ignition source must be present. The ignition source must occur simultaneously with the fuel vapours and air being mixed at the point of ignition within the fuel’s range of flammability. For propane, the flammability range is 2.4 to 9.5 percent volume in air, and requires an ignition temperature of 493⁰ to 549⁰ C. Below 2.4 per cent, the mixture is too lean to ignite. Above 9.5 percent, the mixture is too rich to ignite. Removing one or more of the three components removes the fire hazard.

Propane Liquid Transfer

The transfer of propane liquid between the bulk transport vehicle and the consumer’s cylinder or tank is a closed system with the delivery hose fill nozzle being threaded to create a leak tight seal to the fill valve of the propane container prior to the transfer of liquid propane taking place.

A minimal amount of controlled propane vapour/liquid is released to the atmosphere during the filling process through the fixed liquid level gauge. The gauge indicates when the propane container is filled to its maximum permitted volume. Once the container is filled, the gauge is shut off, stopping the release of propane vapour to the atmosphere.

The fill nozzle releases a legislated amount of propane liquid, approximately 2 to 4 cc to the atmosphere when the nozzle is first loosened from the container’s fill valve. This propane, along with any released from the fixed liquid level gauge, is well dispersed by the time the fill nozzle is removed from the fill valve of the container. If a static electric arc should occur at this point, there is no fuel to ignite.

The fill nozzle releases a legislated amount of propane liquid, approximately 2 to 4 cc to the atmosphere when the nozzle is first loosened from the container’s fill valve. This propane, along with any released from the fixed liquid level gauge, is well dispersed by the time the fill nozzle is removed from the fill valve of the container. If a static electric arc should occur at this point, there is no fuel to ignite.

Preventing Fire Hazards

Fire hazards, when filling customer’s propane containers, are controlled in several ways:

- Fill valves on the propane cylinders and tanks are made of brass, eliminating sparks from metal-to-metal contact;

- The metal propane-receiving cylinders and tanks are installed in contact with the ground;

- The actual transfer of liquid propane to the cylinder or tank is a threaded connection within a closed system, eliminating a static electric charge build-up due to liquid flow from arcing during the fill process;

- The B149.2 Code governs the distances that cylinders and tanks must be located from a source of ignition;

- Propane cylinders and tanks are filled outdoors in well-ventilated areas;

- Propane released during the filling process is low pressure and well dissipated by the time the fill nozzle is disconnected from the brass fill valve; and

- Operators are required to wear clothing which will not generate static electric charge while transferring propane.

The seven items listed above prevent the three essential components occurring simultaneously, which are needed to have an area or process classified as a fire hazard.

Therefore, the volume filling of a consumer’s cylinder or tank does not create a fire hazard. In addition, the existing operating procedures and equipment utilized satisfy the requirement that precautions are to be taken to prevent electrostatic discharge during the transfer process.

Conclusions

Current industry practices provide suitable preventative measures to avoid ignition of any propane released to the atmosphere during the filling of consumer propane containers. Therefore the need for bonding between a propane bulk transport vehicle and propane containers during the transfer process is not required.

There are no legislative requirements that require a person to bond between a propane bulk transport and a customer’s cylinders or tanks during the transfer process. The only legislated requirement to ground or bond is provided in the TDG Regulations where a fire hazard exists or precautions to prevent electro-static discharge have not been taken.

As stated above, current industry practices provide suitable preventative measures to avoid ignition of any propane released to the atmosphere during the filling of consumer propane containers. Therefore, the TDG Regulations do not apply and the need for bonding between a propane bulk transport vehicle and propane containers during the transfer process is not required.

View PDF

Transport Canada has proposed changes to the TDG Regulations that will support harmonization of the regulations with international standards. Some of the proposed changes affecting the propane industry include:

Transport Canada has proposed changes to the TDG Regulations that will support harmonization of the regulations with international standards. Some of the proposed changes affecting the propane industry include: