This article, related to the adoption of 2015 versions of B149 codes, first appeared in the 2015 Jul/Aug edition of Propane Canada Magazine.

I recently chaired the CSA B149.1 Natural Gas & Propane Installation Code Technical Committee meeting and attended as a member of the CSA B149.2 Propane & Storage & Handling Code Technical Committee meeting Niagara Falls, Ontario.

As you are all aware CSA will be publishing the latest editions of the B149 series of Codes in August 2015. I thought this would be an opportune time to provide information on the provincial and territorial adoption dates of the Codes and to reiterate a couple of sections of the new Code that I believe need to be highlighted, namely maintenance and operating procedures and PRV replacement in cylinders.

Also, this edition of Propane Canada magazine is focusing on temporary heat; so I thought it would be appropriate if I highlighted some of the key regulatory changes coming in the next Code edition with respect to construction heating.

Adoption of 2015 CSA Codes

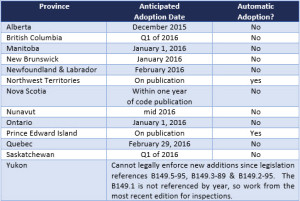

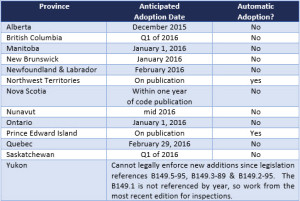

One of the agenda items was the adoption of the 2015 B149 series of codes. The following chart provides the latest proposed adoption dates for each of the provinces and territories. While this is the latest information available it is best to follow up on a regular basis with your provincial or territorial Authority Having Jurisdiction to see if the dates listed will actually be implemented.

Why You Need to Obtain the 2015 Codes

B149.2 Edition

The following are some of the highlights of the 2015 edition of the B149.2 Propane Storage & Handling Code:

- Transfer of clauses to other standards in the B149 Series to make the Code more comprehensive and streamlined;

- New definitions for construction sites, cylinders in storage and connected for use;

- New clauses for construction sites, tank heaters, vaporizer installations and propane storage facility operation and maintenance.

B149.1 Edition

The following are some of the highlights of the 2015 edition of the B149.1 Natural Gas & Propane Installation Code:

- Updated scope provides guidance on metallic fittings, stainless steel tub-ing, pressure regulators for propane vehicle usage, direct gas-fired pro-cess air heaters and more;

- Consolidated clauses from other Codes in the B149 Series make the Code more comprehensive and streamlined;

- New clauses for mobile homes, rec-reational vehicles, highway vehicles, outdoor food service units, and wash-mobiles include specialized re-quirements;

- Simplified references and definitions allow for improved application of the standard’s clauses.

Pre-Order Codes

CSA is currently offering, on their web-site, several different 2015 B149 Code packages that you can pre-order. CSA will also be publishing a handbook for the B149.1 Code. The latest technological advancement is a complete inter-active version of the B149.1-15 and the B149.1-15 Handbook for your iOS or Android tablet or mobile device.

New Propane Facility Maintenance Requirements

The purpose of the new clauses in the code is to provide a minimum standard for the operation and maintenance of propane facilities and equipment. The new clauses apply to tank systems, filling plants, container refill centres and other facilities where liquid propane is piped to a vaporizer or process. Because there are many variables, it is not possible to prescribe a set of operation and maintenance procedures that will be adequate from the standpoint of safety in all cases without being burdensome and, in some cases, impractical. Industry association publications and training programs provide guidance to individuals preparing site specific procedures and may be referenced. The proposed clauses establish a baseline or minimum standard.

The maintenance procedures are to cover testing, inspection, monitoring and documenting of the equipment, its repair, and general upkeep.

There is also a requirement for persons who perform maintenance on facility propane systems to be trained in the hazards of the system and in the maintenance and testing procedures applicable to the facility.

Replacement of PRVs for Propane Cylinders with Dome Covers

This requirement addresses the conflict between the B149.2 Code and the CSA-B339 Standard currently adopted by Transport Canada. The new clause means that the owner of a propane cylinder equipped with a pressure relief valve, previously exempted from replacement by their installation under the dome cover, will now have no conflicting requirement to be used as an argument for not replacing the pressure relief valve at the time of the 10-year cylinder inspection and requalification.

In fact, the new clause is very specific by stating that the PRV is to be removed and replaced with either a new relief valve or one that has been tested to and complies with CGA S 1.1, and found acceptable for use. The clause also requires that a replacement valve has the PRV and dip tube length sized for the cylinder.

There are also new record-keeping requirements listed in the Code which require the facility conducting the visual inspection and requalification to maintain records showing the results of the inspection and requalification until the date of expiration of the requalification period; or the date the cylinder is reinspected.

Personally, it is my opinion that anyone not already replacing the PRV, at the time of requalification of cylinders, such as 420 lb. propane cylinders have been putting non-compliant propane cylinders back into service. The requirement to replace the PRV at the time of the visual inspection and requalification for PRVs protected by a dome cover has been in the CSA-B339 for several years.

Temporary Construction Heat

The chart indicates that provinces will be adopting the 2015 Codes in the middle of this heating season. This means that you must be aware of the new and amended requirements for temporary construction heat. The main focus of the new requirements is the storage, handling and use of propane cylinders at construction sites.

In order to understand how the new requirements will impact their day-to-day activities, cylinder delivery and bulk truck drivers who service the sites must have the knowledge of how to comply with the new requirements.

New 2015 B149.2 Definitions

Connected for Use – this new definition is to clear up the confusion as to whether the propane cylinder is in use or storage when connected to a construction heater and the construction heater is not operating. The definition stipulates that a propane cylinder connected to an approved appliance (construction heat-er) regardless of whether the heater is operating or not is to be considered in use, not storage as some have interpret-ed in the past.

Construction Site – the clause expands on what exactly is a construction site and provides the guidance as to when the site can be considered a construction site for the storage, installation, and use of propane cylinders.

New or Amended Clauses

Cylinder Not Connected for Use – requires cylinders not connected for use to be housed in acceptable storage sites and further clarifies that a propane cylinder connected for use is not considered in storage.

Storage of Cylinders – Provides storage requirements and, under certain conditions, permits cylinders to be stored on the roof of buildings under construction and clarifies acceptable “outdoor” storage by identifying proper and safe storage options that reflect conditions on construction sites. The requirements are based on the hazards (gas accumulation, vehicular traffic, hoisting, etc.), rather than focusing on the location alone.

Presently, rules from various parts of the Code that were not intended to address construction activities are being referenced to regulate construction activities. Even with changes to the 2010 version, it is a struggle to understand which sections of the B149.2 are likely to be applied on construction sites by an inspector. The result is confusion for workers and trainers on what constitutes compliance, in-consistency in enforcement, and disagreement on the job site over safety.

Moving Cylinders – When moving propane cylinders on construction sites by elevator, hoist, or escalator, it was only assumed that other clauses within the Code not specifically related to a construction site would not be referenced and applied on construction sites. The new specific clause with some modification for construction, makes the acceptable means clear to both users and regulators.

In Conclusion

It’s imperative that supervisors, propane technicians and those who deliver cylinders and bulk propane are familiar with the latest Code requirements. To be proactive, a person should order and obtain the latest editions of the Codes from CSA as soon as the Codes are published in August 2015. This will give an opportunity to train on the latest requirements and to understand the impact these new requirements will have on your company prior to their adoption by the Authority Having Jurisdiction in your province or territory.

The Fuels Learning Centre offers training programs addressing the 2015 Code requirements for cylinder requalification (Visual Inspection & Requalification of Propane Cylinders – SO01) and the use of temporary construction heat (Construction Heaters and Propane Cylinders at Construction Sites – AV02).

View PDF

On January 20, 2017, the British Columbia Safety Authority (BCSA) issued Safety Order SO-GA 2017-01 entitled “Installation or Use of Natural Gas and Propane Fireplaces Manufactured by Security Fireplaces – Models SRGH36, SBGH36, DV73 and DV71″.

On January 20, 2017, the British Columbia Safety Authority (BCSA) issued Safety Order SO-GA 2017-01 entitled “Installation or Use of Natural Gas and Propane Fireplaces Manufactured by Security Fireplaces – Models SRGH36, SBGH36, DV73 and DV71″.