Tag Archives: B149.2

SaskPower Issues Bulleting Related to Upcoming Gas Code Meetings

Measurement Canada Releases Revision 6 of Bulletin C-03 Related to the Filling of Propane Cylinders

Adoption of 2015 Versions of B149 Codes

This article, related to the adoption of 2015 versions of B149 codes, first appeared in the 2015 Jul/Aug edition of Propane Canada Magazine.

I recently chaired the CSA B149.1 Natural Gas & Propane Installation Code Technical Committee meeting and attended as a member of the CSA B149.2 Propane & Storage & Handling Code Technical Committee meeting Niagara Falls, Ontario.

As you are all aware CSA will be publishing the latest editions of the B149 series of Codes in August 2015. I thought this would be an opportune time to provide information on the provincial and territorial adoption dates of the Codes and to reiterate a couple of sections of the new Code that I believe need to be highlighted, namely maintenance and operating procedures and PRV replacement in cylinders.

Also, this edition of Propane Canada magazine is focusing on temporary heat; so I thought it would be appropriate if I highlighted some of the key regulatory changes coming in the next Code edition with respect to construction heating.

Adoption of 2015 CSA Codes

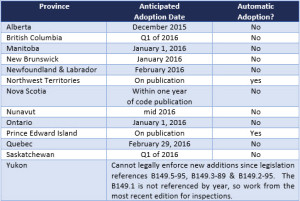

One of the agenda items was the adoption of the 2015 B149 series of codes. The following chart provides the latest proposed adoption dates for each of the provinces and territories. While this is the latest information available it is best to follow up on a regular basis with your provincial or territorial Authority Having Jurisdiction to see if the dates listed will actually be implemented.

Why You Need to Obtain the 2015 Codes

B149.2 Edition

The following are some of the highlights of the 2015 edition of the B149.2 Propane Storage & Handling Code:

- Transfer of clauses to other standards in the B149 Series to make the Code more comprehensive and streamlined;

- New definitions for construction sites, cylinders in storage and connected for use;

- New clauses for construction sites, tank heaters, vaporizer installations and propane storage facility operation and maintenance.

B149.1 Edition

The following are some of the highlights of the 2015 edition of the B149.1 Natural Gas & Propane Installation Code:

- Updated scope provides guidance on metallic fittings, stainless steel tub-ing, pressure regulators for propane vehicle usage, direct gas-fired pro-cess air heaters and more;

- Consolidated clauses from other Codes in the B149 Series make the Code more comprehensive and streamlined;

- New clauses for mobile homes, rec-reational vehicles, highway vehicles, outdoor food service units, and wash-mobiles include specialized re-quirements;

- Simplified references and definitions allow for improved application of the standard’s clauses.

Pre-Order Codes

CSA is currently offering, on their web-site, several different 2015 B149 Code packages that you can pre-order. CSA will also be publishing a handbook for the B149.1 Code. The latest technological advancement is a complete inter-active version of the B149.1-15 and the B149.1-15 Handbook for your iOS or Android tablet or mobile device.

New Propane Facility Maintenance Requirements

The purpose of the new clauses in the code is to provide a minimum standard for the operation and maintenance of propane facilities and equipment. The new clauses apply to tank systems, filling plants, container refill centres and other facilities where liquid propane is piped to a vaporizer or process. Because there are many variables, it is not possible to prescribe a set of operation and maintenance procedures that will be adequate from the standpoint of safety in all cases without being burdensome and, in some cases, impractical. Industry association publications and training programs provide guidance to individuals preparing site specific procedures and may be referenced. The proposed clauses establish a baseline or minimum standard.

The maintenance procedures are to cover testing, inspection, monitoring and documenting of the equipment, its repair, and general upkeep.

There is also a requirement for persons who perform maintenance on facility propane systems to be trained in the hazards of the system and in the maintenance and testing procedures applicable to the facility.

Replacement of PRVs for Propane Cylinders with Dome Covers

This requirement addresses the conflict between the B149.2 Code and the CSA-B339 Standard currently adopted by Transport Canada. The new clause means that the owner of a propane cylinder equipped with a pressure relief valve, previously exempted from replacement by their installation under the dome cover, will now have no conflicting requirement to be used as an argument for not replacing the pressure relief valve at the time of the 10-year cylinder inspection and requalification.

In fact, the new clause is very specific by stating that the PRV is to be removed and replaced with either a new relief valve or one that has been tested to and complies with CGA S 1.1, and found acceptable for use. The clause also requires that a replacement valve has the PRV and dip tube length sized for the cylinder.

There are also new record-keeping requirements listed in the Code which require the facility conducting the visual inspection and requalification to maintain records showing the results of the inspection and requalification until the date of expiration of the requalification period; or the date the cylinder is reinspected.

Personally, it is my opinion that anyone not already replacing the PRV, at the time of requalification of cylinders, such as 420 lb. propane cylinders have been putting non-compliant propane cylinders back into service. The requirement to replace the PRV at the time of the visual inspection and requalification for PRVs protected by a dome cover has been in the CSA-B339 for several years.

Temporary Construction Heat

The chart indicates that provinces will be adopting the 2015 Codes in the middle of this heating season. This means that you must be aware of the new and amended requirements for temporary construction heat. The main focus of the new requirements is the storage, handling and use of propane cylinders at construction sites.

In order to understand how the new requirements will impact their day-to-day activities, cylinder delivery and bulk truck drivers who service the sites must have the knowledge of how to comply with the new requirements.

New 2015 B149.2 Definitions

Connected for Use – this new definition is to clear up the confusion as to whether the propane cylinder is in use or storage when connected to a construction heater and the construction heater is not operating. The definition stipulates that a propane cylinder connected to an approved appliance (construction heat-er) regardless of whether the heater is operating or not is to be considered in use, not storage as some have interpret-ed in the past.

Construction Site – the clause expands on what exactly is a construction site and provides the guidance as to when the site can be considered a construction site for the storage, installation, and use of propane cylinders.

New or Amended Clauses

Cylinder Not Connected for Use – requires cylinders not connected for use to be housed in acceptable storage sites and further clarifies that a propane cylinder connected for use is not considered in storage.

Storage of Cylinders – Provides storage requirements and, under certain conditions, permits cylinders to be stored on the roof of buildings under construction and clarifies acceptable “outdoor” storage by identifying proper and safe storage options that reflect conditions on construction sites. The requirements are based on the hazards (gas accumulation, vehicular traffic, hoisting, etc.), rather than focusing on the location alone.

Presently, rules from various parts of the Code that were not intended to address construction activities are being referenced to regulate construction activities. Even with changes to the 2010 version, it is a struggle to understand which sections of the B149.2 are likely to be applied on construction sites by an inspector. The result is confusion for workers and trainers on what constitutes compliance, in-consistency in enforcement, and disagreement on the job site over safety.

Moving Cylinders – When moving propane cylinders on construction sites by elevator, hoist, or escalator, it was only assumed that other clauses within the Code not specifically related to a construction site would not be referenced and applied on construction sites. The new specific clause with some modification for construction, makes the acceptable means clear to both users and regulators.

In Conclusion

It’s imperative that supervisors, propane technicians and those who deliver cylinders and bulk propane are familiar with the latest Code requirements. To be proactive, a person should order and obtain the latest editions of the Codes from CSA as soon as the Codes are published in August 2015. This will give an opportunity to train on the latest requirements and to understand the impact these new requirements will have on your company prior to their adoption by the Authority Having Jurisdiction in your province or territory.

The Fuels Learning Centre offers training programs addressing the 2015 Code requirements for cylinder requalification (Visual Inspection & Requalification of Propane Cylinders – SO01) and the use of temporary construction heat (Construction Heaters and Propane Cylinders at Construction Sites – AV02).

Nova Scotia Labour & Advanced Education Issues Directive Related to Flare Stacks and Vehicle Parking at Bulk Plants

This Directive (FSD 2015-003) clarifies the requirement that propane may not be released to the atmosphere and that an approved flare stack must be used to burn off propane from tanks requiring emptying prior to repairs. In addition, the Directive clarifies that only vehicles required for the operation of the bulk plant be parked within the fenced area. Employee and visitor parking is not allowed in the fenced area.

This Directive (FSD 2015-003) clarifies the requirement that propane may not be released to the atmosphere and that an approved flare stack must be used to burn off propane from tanks requiring emptying prior to repairs. In addition, the Directive clarifies that only vehicles required for the operation of the bulk plant be parked within the fenced area. Employee and visitor parking is not allowed in the fenced area.

BCSA Issues Bulletin Related to Emergency & Natural Disaster Protocol for Electrical & Gas Equipment Safety

BCSA Issues Directive Related to the Permit Requirements for Propane Tanks

Impacts of Regulatory Changes for Construction Heater Lessors

This article, related to the impact of propane regulatory changes to lessors of construction heating equipment, was initially prepared for distribution at the Ontario Chapter of the Canadian Rental Association’s 2015 annual meeting and trade show.

Introduction

Over the past several months, the Fuels Learning Centre has been pleased to provide information pertaining to changes to the regulations affecting the use of construction heaters and cylinder storage at construction sites. This information was printed in three recent Canadian Rental Association (CRA) Ontario newsletters. This article provides a summary of the propane regulatory changes that have been amended, added and deleted in the CAN/CSA B149.2 Propane Storage and Handling Code that affect the use and storage of propane cylinders and equipment at construction sites and industrial storage.

In 2015, the Canadian Standards Association (CSA) will issue new versions of the B149 Codes scheduled for release by CSA in August 2015. The 2015 Codes are meant to replace the current 2010 Codes in use. For the propane construction site user, it can be a challenge to determine what has been deleted, added or amended, since the last Code was published.

The 2015 editions of the Code is the completion of a 5-year code cycle that CSA uses to keep the Codes updated to address new technologies, new installation materials, and changing building environments.

Training Requirements

Provincial Regulations require the lessor of a construction heater to ensure that the lessee is instructed in the safe installation and use of the construction heater and its components and that persons who install propane cylinders and propane fired construction heaters and torches hold a recognized Record of Training (ROT) for the purpose.

This does create some issues as the current Record of Training (ROT) retraining requirements are once every 3 years, which means that people can actually be working in the field for up to 3 years before they are trained on the new regulatory requirements.

Given that 2015 is the year for the issuance of new codes it may be advisable for employers in certain segments of the industry such as gas technicians, propane tank truck and cargo liner drivers, cylinder truck operators and construction site operators, to have their employees trained on the new requirements rather than wait until such time that the person’s ROT is up for renewal.

The adoption of the 2015 Code is done by each province and territory separately with some Authorities Having Jurisdiction (AHJ) adopting the Codes immediately and others taking several years. A person must use the most current Code adopted in their Province or Territory for new or upgrading propane installations. In addition, each Province or Territory can, when adopting the Codes add, amend or delete clauses from the Code by way of their Code Adoption Document (CAD).

Ontario Adopts Portions of 2015 Code

The Technical Standards & Safety Authority (TSSA) issued an amendment to their Propane Code Adoption Document which is effective October 1, 2014. TSSA felt that new requirements in the 2015 version of the Code were considered important to be implemented in Ontario right away and addresses gaps in the current Code to enhance safety. In particular, the new requirements pertaining to cylinder use and storage at construction sites became effective as of October 1, 2014.

The Technical Standards & Safety Authority (TSSA) issued an amendment to their Propane Code Adoption Document which is effective October 1, 2014. TSSA felt that new requirements in the 2015 version of the Code were considered important to be implemented in Ontario right away and addresses gaps in the current Code to enhance safety. In particular, the new requirements pertaining to cylinder use and storage at construction sites became effective as of October 1, 2014.

Once the Codes and Standards are adopted there will be an immediate training need for persons who perform work that is regulated by these documents. In Ontario, this was October 1, 2014, which means training programs must reflect the latest regulatory requirements as of October 1, 2014, for Ontario and in other provinces later in 2015. Construction heater lessors should ensure their training providers have updated their programs to reflect the new requirements. The Fuels Learning Centre currently offers three programs related to the safe installation and operation of construction heaters and torches reflecting all the new regulatory requirements.

- Construction Heaters, Torches & Propane Cylinders at Construction Sites (AV01)

- Construction Heaters and Propane Cylinders at Construction Sites (AV02)

- Hand-Held Torches and Propane Cylinders at Construction Sites (AV03)

If training is required on both construction heaters and torches, then AV01 is the correct course to take. If training is required only for construction heaters, then AV02 is the correct course while AV03 focuses on hand-held torches only.

New Definitions and Clauses

Construction Site

The new term defines a Construction Site as “a temporary worksite involving construction activities such as the erection, alteration, and dismantling or demolition of a building or equipment, re-roofing of a building, or digging”. The term was added to identify that the handling of cylinders and propane apparatus in use or in storage at construction sites are subject to significantly differing situations.

Propane Cylinder Installation

Clause 5.10 originally restricted cylinders from being installed under any fire escape, stairway, or ramp used as a means of egress from a building. The clause has been amended to read “container” so the restriction now applies to both cylinders and tanks.

Connected for Use

Means a propane container that is properly connected to an approved appliance in accordance with the provisions of this code. The rationale behind adding this new term relates to disputes which have occurred in the field over whether or not cylinders that are properly connected to an appliance that is not running, and which may or may not be turned on for use, are in storage and therefore subject to the requirements for storing cylinders. Properly connected cylinders that remain connected for use, intermittent use, or future use, should not be subject to storage requirements.

New Clause 6.1.16

Cylinders in storage or connected for use, cylinder-regulating equipment, or a cylinder manifold, shall not be exposed to temperatures in excess of 125 degrees Fahrenheit or 50 degrees Celsius. This clause was added to limit the temperatures to which propane cylinders, regulating equipment or cylinder manifolds can be exposed.

Use of OPDs

Clause 6.1.2 was amended to harmonize with US requirements. NFPA 58-2008 states that cylinders with 4 lb. (1.8 kg) through 40 lb. (18 kg) propane capacity for vapour service shall be equipped or fitted with a listed overfill protection device; the current Canadian requirement starts at zero, not 4 lbs. (1.8 kg) as in the US. The Clause now states that except for (a) cylinders used in industrial truck service; and (b) cylinders identified and used for industrial welding and cutting gases, refillable vapour service cylinders manufactured after January 1, 2008 with a capacity of 4 lbs (1.8 kg) through 40 lb (18.2 kg shall be equipped with an overfill prevention device (OPD) in compliance with UL 2227.

Clause 6.1.2 was amended to harmonize with US requirements. NFPA 58-2008 states that cylinders with 4 lb. (1.8 kg) through 40 lb. (18 kg) propane capacity for vapour service shall be equipped or fitted with a listed overfill protection device; the current Canadian requirement starts at zero, not 4 lbs. (1.8 kg) as in the US. The Clause now states that except for (a) cylinders used in industrial truck service; and (b) cylinders identified and used for industrial welding and cutting gases, refillable vapour service cylinders manufactured after January 1, 2008 with a capacity of 4 lbs (1.8 kg) through 40 lb (18.2 kg shall be equipped with an overfill prevention device (OPD) in compliance with UL 2227.

Operators of propane torches must be aware of this requirement to ensure the cylinders to which they are connecting hand-held torches are equipped with an OPD valve unless the cylinder was manufactured before 2008. It’s important to note that when cylinders are requalified, an OPD valve will be installed, therefore, the only cylinders that may not have an OPD valve were those manufactured between November 2004 and January 2008.

Operators of propane torches must be aware of this requirement to ensure the cylinders to which they are connecting hand-held torches are equipped with an OPD valve unless the cylinder was manufactured before 2008. It’s important to note that when cylinders are requalified, an OPD valve will be installed, therefore, the only cylinders that may not have an OPD valve were those manufactured between November 2004 and January 2008.

Cylinder Requalification

Propane cylinders must be visually inspected and requalified once every 10 years starting with the date of manufacture. Clause 6.1.5 has been amended to remove the previous requirements for the 10-year cylinder inspection and requalification from the Code. The clause now states that refillable cylinders shall not be refilled if they are due for requalification as prescribed by requirements of the CSA Standard B339 Cylinders, Spheres & Tubes for the Transportation of Dangerous Goods.

Users of propane cylinders at the construction site should be aware that a cylinder cannot be refilled if the requalification is past-due.

Single-trip Type Propane Cylinders

Clause 6.4.5 has been amended to clarify that Specification TC-39M and aerosol containers cannot be refilled. In addition, Clause 6.5.1.4, which deals with the number of aerosol containers and TC-39 non-refillable cylinders which may be stored in a dwelling, was amended for correctness.

Single-trip small capacity propane cylinders are often used on the construction site and the site manager should be aware of the storage requirements and that these cylinders cannot be refilled.

Addition to Scope

The scope of the Code has been amended to include maintenance as a requirement for containers and equipment to be used for propane at customer locations, in distribution locations, and filling plants.

The rationale for this change was that regardless of who owns the propane storage container, be it the propane distributor or customer, the container must be properly maintained. Safety requirements for systems and components should not be different for various owners.

Increase in Cylinder Size at Exchange Locations

The Code was amended to delete the 20 lb. maximum cylinder size that may be stored at a cylinder exchange. The rationale provided is that due to a demand from RV customers, 30 lb. cylinders are being offered at exchange locations. The safety concerns of 30 lb. cylinders are not different from those of 20 lb. cylinders. Maintaining the cabinet maximum capacity of 500 lb. (25 x 20 lb., or 16 x 30 lb., or combination thereof) maintains the same risk and requirements of a single full exchange cabinet.

Cylinder Storage Cages

To reflect current acceptable practices and to provide clear minimum design criteria that allow innovation, Clause 6.5.1.15 has been amended so that when cylinders are enclosed in a cabinet, cage, or other means not covered under clause 6.5.2.7 or 6.5.10, the confinement means shall:

- be supplied with a top cover;

- be made of noncombustible material and be structurally sound with no openings greater than 4 square inches (25.8 cm²);

- have at least two sides constructed to provide equal ventilation through openings at the top and bottom of the side providing, as a minimum, the equivalent total opening of 15% open area on each side panel;

- not restrict the dispersion of any fuel gas leak to ensure it is well ventilated;

- have its base on a firm level footing in an upright position; and,

- not be located against other objects, or have objects attached that restrict ventilation.

Storage of Cylinders & Sources of Ignition

To clarify requirements for storing cylinders Clause 6.5.1.5 has been amended to require that any cylinder in storage shall not be exposed to an open flame or other sources of ignition, and shall be protected from tampering or damage by fencing or equivalent means.

Cylinders Stored at Construction Sites

Clause 6.5.3.1.2 has been amended to clarify the storage requirements, the clause indicates that a stored cylinder shall be located in an area that complies with the requirements of 6.5.3.2., and the storage area shall be outdoors.

- When the conditions of this clause are met, a storage area utilizing a structure with overhead protection, walls, or both, meets the intent of outdoor storage.

- The structure is designed to be enclosed by no more than two solid walls on the level the cylinder(s) are stored;

- The cylinders are located within 25 ft. (7.6 m) of an open area of the perimeter opening;

- When a wall of the structure is a part a building, that building must be under construction, repair, improvement, and there must be no inhabited dwelling units or inhabited sections of that building;

- There are no openings through which gas may travel to a lower elevation, such as an open stairway on the floor on which the cylinders are located; and

- There are no wall openings through which gasses could travel into another structure or building.

- Cylinders may be stored in a cabinet that meets clause 6.5.2.4, in the storage area.

- A storage area may be on a roof of a structure or building provided the conditions of clause 6.5.3.9 are met.

These amendments clarify acceptable “outdoor” storage by identifying proper and safe storage options that reflect conditions on construction sites, and is based on the hazards (gas accumulation, vehicular traffic, hoisting, etc.), rather than focusing on the location alone.

Presently, rules from various parts of the Standard that were not intended to address construction activities are being referenced to regulate construction activities. Even with changes to the 2010 version, it is a struggle to understand which sections of the B149.2 are likely to be applied on construction sites by an inspector.

The result is confusion for workers and trainers on what constitutes compliance, inconsistency in enforcement, and disagreement on the job site over safety.

Clause 6.5.3.2 has also been amended to clarify storage of propane cylinders at construction sites and requires that cylinders in storage shall;

- be stored in an area that:

- provides protection from tampering;

- is free from vehicular or mobile equipment travel, or protected by barriers or the equivalent;

- has “NO SMOKING” signs which are prominently displayed. These signs shall be in accordance with Clause 7.12.3; and

- meets the requirements of table 6.3.

- be placed such that the relief valve on any cylinder is not less than 3 ft. (1m) horizontally from any building opening that is below the level of the relief valve discharge;

- be placed such that the relief valve discharge is not less than 10 ft. (3 m) on the horizontal plane from the air intake of any appliance or air-moving equipment;

- be stored in an area that meets clause 6.5.1 and 6.5.3.9.

The rationale behind these amendments is that construction sites occur under a variety of wide-ranging circumstances. Storage requirements that are intended for industrial settings are too limiting and expose cylinders to hazards associated with construction activities. Cylinder storage on construction sites requires reasonable objectives which also address the worksite hazards.

Movement of Propane Cylinders

Clause 6.5.3.8 has been amended to address the movement of propane cylinders around the construction site and indicates that moving a propane cylinder from one level to another level or the roof of a building may be done using:

- a freight, service elevator, or construction hoist; or,

- if by public passenger elevator or escalator, only the person(s) involved with the cylinder shall be in the elevator or on the escalator.

When moving a propane cylinder to or from the roof or one level to another of a building, each cylinder valve outlet shall be closed, plugged and the valve protective cap or collar in place.

When moving a propane cylinder to or from the roof or one level to another of a building, each cylinder valve outlet shall be closed, plugged and the valve protective cap or collar in place.

Storage of Propane Cylinders on Roofs

New clause 6.5.1.14 permits propane cylinders to be stored on roofs. Cylinders to be stored on roofs must meet certain conditions. The clause directs the reader to a specific clause 6.5.3.9 that details the conditions under which a cylinder may be stored on the roof of a structure under construction. The Clause indicates that a cylinder which contains propane liquid or vapour shall not be stored on the roof of a building unless it is stored in accordance with clause 6.5.3.9, or connected for use in accordance with clause 6.8.

New clause 6.5.3.9 – Cylinders on Building Rooftops states that cylinders on building rooftops shall comply with the following:

- A propane cylinder shall not be on the roof of a building unless the cylinder is to be connected for work undertaken on the roof during the current or the immediately following work shift.

- Cylinders not in use shall be stored in accordance with provisions of clause 6.5.3.2 and the following shall additionally be met:

- the cylinder(s) weight shall not exceed the net load capacity of the roofing structure as specified by the building owner or management;

- the storage area shall be at least 10 ft. (3m) from the building edge or a change in elevation of more than 3 feet (1m);

- cylinders shall be secured to maintain the cylinder in its proper storage position during inclement weather; and

- all cylinders shall be removed upon completion of the work.

- Cylinders properly connected in an approved manner to the appliance it serves shall be adequately secured from inclement weather.

- No more than 1,000 lb. (450 kg) of propane in total capacity shall be stored on the roof.

These amendments provide the following benefits.

- Retains the original intent of the 2000 change regarding cylinder storage on rooftops for permanent appliance installations – limiting rooftop cylinder storage on permanent installations.

- Provides clear guidance around cylinder use and storage on rooftops for roofers.

- Provides for storage of cylinders on the roof to reduce the number of times cylinders are hoisted, lowered, and manhandled, and the hazards associated with moving cylinders, and to address storage security.

- Limits roof top storage to a practical number of cylinders.

- Adds additional protection for firefighters with a new requirement to post signs at occupied buildings.

Truck-to-Truck Propane Transfers

This article, related to truck-to-truck propane transfers, first appeared in the January/February 2015 edition of Propane Canada magazine.

There are times when there is a need to transfer liquid propane from one propane transport vehicle to another. Typical uses for truck-to-truck propane liquid transfers are where a smaller tank truck is attached to a barge for island deliveries and specialty off-road tank trucks used for remote deliveries in the oil patch and mine sites. The other times would be in cases of emergencies such as when there is a power outage at the bulk plant or a tank truck or cargo liner tank needs evacuating due to an accident.

There are times when there is a need to transfer liquid propane from one propane transport vehicle to another. Typical uses for truck-to-truck propane liquid transfers are where a smaller tank truck is attached to a barge for island deliveries and specialty off-road tank trucks used for remote deliveries in the oil patch and mine sites. The other times would be in cases of emergencies such as when there is a power outage at the bulk plant or a tank truck or cargo liner tank needs evacuating due to an accident.

Regulatory Requirements

The actual loading, transportation, and unloading of cargo liners and tank trucks fall under the Transportation of Dangerous Goods Regulations (TDG). The loading aspect falls under the task of “offering for transport”. The TDG Regulations do not specifically address truck-to-truck liquid propane transfers but provide general requirements that must be met during the loading and unloading process regardless of where the transfer takes place. Therefore, one must ensure that all of the requirements legislated under the TDG

Regulations are met.

The TDG regulations, through the adoption of the CSA B620 Highway Tank and Portable Tanks for the Transportation of Dangerous Goods standard stipulate that when loading or unloading a cargo liner or tank truck, you must, during the transfer process, use the fail-safe brake inter-lock system and chock blocks at the rear wheels of both units involved in the transfer to ensure that both units involved do not move.

The CSA B620 general requirements require that the following conditions must also be met prior to starting the transfer process:

- Connections must be inspected to ensure the propane liquid will be transferred into the proper connection;

- The space available in the receiving tank must be verified to ensure that it is sufficient to accommodate the quantity of liquid propane to be transferred;

- When remotely opening the internal safety control valve (ISC) , you are to have an unobstructed view of the cargo liner tank, delivery hose, and tank truck being filled, to the maxi-mum extent practicable; and

- The periodic inspection or test intervals for tanks involved in the transfer must be up to date.

During the transfer process:

- The driver is responsible for the transfer and must have been trained in propane hazards and emergency procedures;

- The driver is to remain alert, within easy access of the supply and receiving flow shutdown controls, and to the extent possible, with the hose and both tanks in clear view except for brief periods to operate controls or to check the receiving tank;

- When equipped with an off-truck emergency shutdown system, the driver must be in possession of the control at all times the tank valve is open, within 150 ft. of the tank and 25 ft. of the hose;

- The driver must control the quantity of propane liquid being transferred; and

- Immediately after the liquid propane has been transferred, all valves on both the supply and receiving tank must be closed and secured.

Provincial Regulations

The 2010 CAN/CSA BI49.2 Propane Storage & Handling Code requires that when offering for transport or transporting propane that the requirements of the TDG regulations must be followed.

The 2015 edition of the CAN/CSA B149.2 Propane Storage & Handling Code, to be published in August of 2015, also speaks to this issue. The code stipulates that the contents of a cargo tank or cargo liner may be transferred to the cargo tank on another tank truck or cargo liner in an emergency.

The transfer of propane from a cargo tank or cargo liner for any purpose other than an emergency shall only be per-formed when specifically approved by the authority having jurisdiction.

It should be noted that for the purposes of the above provision, emergency means a sudden, urgent, usually unex-pected occurrence or occasion such as a general power failure, plant mechanical failure, incident, or vehicle mechanical failure requiring immediate action to protect or reduce the hazard to public safety.

Currently, two provinces, British Columbia and Ontario, have issued specific enhanced requirements over and above the TDG requirements as to how truck-to-truck propane liquid transfers are to be carried out in their provinces.

Until such time that the 2015 Code is adopted in your province, you must follow the TDG requirements if your province has not issued additional requirements.

British Columbia

On December 30, 2010, the BC Safety Authority issued Directive # D-G5 101230 1 which outlines the operating procedure that needs to be in place for the tank truck to tank truck transfer of liquid propane along with the required training of the personnel performing this procedure.

On December 30, 2010, the BC Safety Authority issued Directive # D-G5 101230 1 which outlines the operating procedure that needs to be in place for the tank truck to tank truck transfer of liquid propane along with the required training of the personnel performing this procedure.

General Details:

Clause 8.13.3 of the CAN/CSA B149.2-05 allows the transfer of propane product from one tank truck to another tank truck. In order to perform this procedure, an Operating

Procedure accepted by the BCSA must be in place that describes in detail how, when, and where this activity will take place, along with the specific training of the personnel performing this procedure in accordance with accepted industry practice.

Definitions:

Tank truck – A truck chassis and tank assembly as a complete unit for the bulk delivery of propane.

Cargo Liner – A vehicle that is used to transfer propane in which the tank constitutes the main structural member and that is towed by a separate motor vehicle. Note: For the purposes of this Directive, the terms “Tank Truck” and “Cargo Liner” are interchangeable.

Filling Plant (bulk plant) – A facility, the primary purpose of which is the distribution of propane. Such plants have bulk storage and usually have container filling and vehicle transfer facilities on the premises. Bulk plants are considered part of this category.

Specific Details:

The above described Operating Procedure must be developed and delivered to the Provincial Safety Manager – Gas for acceptance. Although Clause 8.13.3 of the CAN/CSA B149.2-05 allows for the transfer of propane from one tank truck to another, this activity shall not be performed by any individual who is not following an accepted Operating Procedure.

The only exception is when a propane emergency exists and where it is decided this practice will reduce the risk of accident or severity of an incident. In this case, a Remedial Measures Advisor from the Liquefied Petroleum Gas Emergency Response Corporation must be in attendance and permission from the Provincial Safety Manager or their designate must be received.

Guideline To Required Operating Procedure:

The following are intended as the minimum requirements:

Filling plants must meet the operating requirements described in section 28 of the Gas Safety. Regulation (GSR) and comply with the CAN/CSA B149.2-05.

Tank trucks or cargo liners must comply with all requirements as contained in the CAN/CSA B149.2-05.

Tank truck to tank truck transfer must be performed only by personnel trained in the Operating. Procedure, qualified as required by section 5.2.10f the CAN/CSA B149.2-05, and authorized in accordance with section 4(1)(d) of the GSR.

The facility complies with all Local Government requirements.

Required clearances and related clauses as stated in the CAN/CSA B 149 .2-05 are adhered to during the transfer process:

- The aggregate amount of propane contained in any offloading tank truck and the approved stationary tank(s) shall not exceed the maximum storage capacity of the stationary tank(s).

- A designated filling plant (bulk plant) used to transfer propane from one tank truck to another tank truck shall be approved by the Local and Provincial authorities having jurisdiction.

Ontario

The Ontario Code Adoption Document FS-211-14, which became effective on Oct. 1, 2014, states that:

The Ontario Code Adoption Document FS-211-14, which became effective on Oct. 1, 2014, states that:

The contents of a tank on a tank truck or a cargo liner shall not be transferred to the cargo tank on another tank truck or cargo liner unless the operation is carried out at a filling plant.

Except for an emergency such as a loss of power due to unexpected natural weather, the transfer of propane from a cargo tank to another tank truck or cargo liner at the filling plant shall be approved.

TSSA will consider the following before granting an approval to transfer propane from a cargo tank to another tank truck or cargo liner at a filling plant:

- The filling plant shall hold a valid license.

- The filling plant shall have a permanent licensed storage capacity of at least the largest tank truck, or the amount of the truck to truck transfer shall be specifically approved by TSSA.

- The transfer shall be performed by a Propane Truck Operator (PTO) certificate holder.

- The risks associated with the operation, including mitigation measures and emergency procedures in place.

- Sufficient space to accommodate both tank trucks without blocking any emergency exits shall be maintained; and

- All requirements and minimum clearances of CSA B149.2-10, including emergency shutoff valves shall be complied with.

Protective Clothing

In closing, remember you are handling liquid propane that can cause serious freezer burns and injury if the liquid comes into contact with your skin. You must, therefore, wear the proper protective clothing and gloves when connecting and disconnecting propane hoses during truck-to-truck transfers.

Training Available

To address your training needs, the Fuels Learning Centre’s “Loading & Unloading Propane Cargo Liners (TO01)” and “Loading and Unloading Propane Tank Trucks (TO02)” courses include the latest requirements for truck to truck liquid propane transfers by providing the specific TOG and provincial requirements.